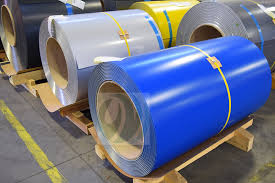

WANtai’s 3105 Color Coated Aluminum Coil is a widely used material in the automotive industry due to its practical properties. This aluminum alloy is valued for its strength, formability, corrosion resistance, and aesthetic appeal, making it suitable for various automotive applications. Below, we discuss the specific benefits of using WANtai’s 3105 Color Coated Aluminum Coil in automotive design.

Durability and Corrosion Resistance

One of the primary benefits of 3105 Color Coated Aluminum Coil is its excellent durability and resistance to corrosion. In the automotive industry, components are often exposed to harsh environmental conditions, including moisture, salt, and chemicals. 3105 Color Coated Aluminum Coil offers a strong barrier against these elements, preventing rust and degradation over time. This ensures that automotive parts made from this material have a longer lifespan, reducing the need for frequent replacements and maintenance.

Lightweight and Fuel Efficiency

3105 Color Coated Aluminum Coil is lightweight, which is a significant advantage in automotive design. Reducing the weight of a vehicle is directly linked to improving fuel efficiency. By using lightweight materials like 3105 aluminum, manufacturers can produce vehicles that consume less fuel, contributing to lower emissions and cost savings for the consumer. The reduced weight also enhances vehicle performance, including acceleration, braking, and handling.

Aesthetic Flexibility

The color coating on WANtai’s 3105 aluminum coil allows for a wide range of aesthetic options in automotive design. The coating provides a smooth, attractive finish that can be tailored to match specific color requirements. This is important for automotive manufacturers looking to offer vehicles with visually appealing designs. The color coated aluminum is not only functional but also adds to the overall aesthetic value of the vehicle, making it more appealing to consumers.

Formability and Manufacturing Efficiency

Another key benefit of 3105 Color Coated Aluminum Coil is its excellent formability. This material can be easily shaped into various forms without cracking or losing its structural integrity. In the automotive industry, this property is crucial as it allows for the production of complex shapes and components. WANtai’s 3105 Color Coated Aluminum Coil can be stamped, rolled, and bent into the necessary shapes, making it a versatile material for different automotive parts, including body panels, trims, and interior components.

The ease of fabrication with 3105 aluminum contributes to manufacturing efficiency. Manufacturers can produce parts more quickly and with less waste, leading to cost savings in the production process. The ability to create precise and complex shapes with this material also ensures that the final products meet the high standards required in the automotive industry.

Thermal Conductivity and Heat Resistance

3105 aluminum offers good thermal conductivity, which is beneficial in automotive applications where heat dissipation is important. Components such as heat shields, engine parts, and other areas where temperature control is critical can benefit from the use of WANtai’s 3105 Color Coated Aluminum Coil. The material helps to manage and dissipate heat effectively, ensuring that the vehicle operates efficiently and safely.

In addition to thermal conductivity, 3105 aluminum is resistant to high temperatures, which prevents warping or degradation when exposed to the heat generated by the engine and exhaust systems. This makes it a reliable material for parts that are in close proximity to high-temperature areas in a vehicle.

Environmental Sustainability

WANtai’s 3105 Color Coated Aluminum Coil is also an environmentally friendly choice for automotive manufacturers. Aluminum is a recyclable material, and using recycled aluminum reduces the environmental impact of production. The recycling process for aluminum requires less energy compared to producing new aluminum, contributing to lower carbon emissions. By using 3105 aluminum, manufacturers can produce vehicles that are not only efficient but also contribute to sustainability efforts.

Cost-Effectiveness

Another important advantage of WANtai’s 3105 Color Coated Aluminum Coil is its cost-effectiveness. While aluminum may be more expensive than some other materials, its long-term benefits make it a cost-effective choice for automotive manufacturers. The durability and corrosion resistance of 3105 aluminum reduce maintenance and replacement costs, while its lightweight nature leads to fuel savings. Additionally, the material’s recyclability further enhances its cost-effectiveness by reducing the need for raw materials.

Safety and Crashworthiness

3105 Color Coated Aluminum Coil also contributes to vehicle safety. The material’s strength and formability allow for the creation of crumple zones that absorb energy during a collision, protecting the occupants of the vehicle. The use of aluminum in the vehicle’s structure helps to maintain rigidity while ensuring that the car can absorb impact forces effectively.

Noise and Vibration Reduction

In automotive design, reducing noise and vibration is important for enhancing the driving experience. 3105 aluminum has sound-dampening properties that help in minimizing road noise and vibrations. This contributes to a quieter and more comfortable ride for passengers. The material’s ability to absorb and dampen vibrations is especially beneficial in components like body panels and structural elements.

Compatibility with Other Materials

WANtai’s 3105 Color Coated Aluminum Coil is also compatible with other materials commonly used in automotive manufacturing. This compatibility allows for easy integration with steel, plastics, and other materials, enabling manufacturers to create multi-material components that combine the best properties of each material. The ability to work well with other materials also facilitates the production of hybrid structures that offer enhanced performance, durability, and efficiency.

Conclusion

WANtai’s 3105 Color Coated Aluminum Coil offers numerous benefits for automotive design, making it a preferred choice for manufacturers. Its durability, lightweight nature, and aesthetic flexibility make it ideal for a wide range of applications, from body panels to interior components. The material’s formability, thermal conductivity, and resistance to corrosion further enhance its suitability for the automotive industry. Additionally, the environmental sustainability and cost-effectiveness of 3105 aluminum make it a responsible and economically viable option for modern vehicle manufacturing. By choosing WANtai’s 3105 Color Coated Aluminum Coil, automotive manufacturers can ensure that their vehicles are both high-performing and visually appealing while contributing to a more sustainable future.

No Comments

Leave Comment